|

|

Bill Brodhead WPB Enterprises Inc

Radon & Vapor Intrusion |

|

|

|

Bill Brodhead WPB Enterprises Inc.

Radon & Vapor Intrusion |

|

|

|

|

Importance of Diagnostics

|

|

Commercial buildings are rarely built on clean gravel. Determining the ease of airflow under the slab and the distance and strength pressure fields can be obtained with increasing negative pressure applied to the sub-slab is crucial to designing and installing an efficient and effective system. Commercial buildings are rarely built on clean gravel. Determining the ease of airflow under the slab and the distance and strength pressure fields can be obtained with increasing negative pressure applied to the sub-slab is crucial to designing and installing an efficient and effective system. The long term energy costs of operating an oversized system can far exceed the initial installation costs. WPB always recommends that accurate and thorough sub-slab pressure field extension (PFE) tests (also called sub-slab communication tests) be performed first before any active soil depressurization (ASD) system is designed and installed. How we accomplish these tests and and use the obtained information is presented below. A separate page describes how we perform residential PFE Testing Procedures |

|

|

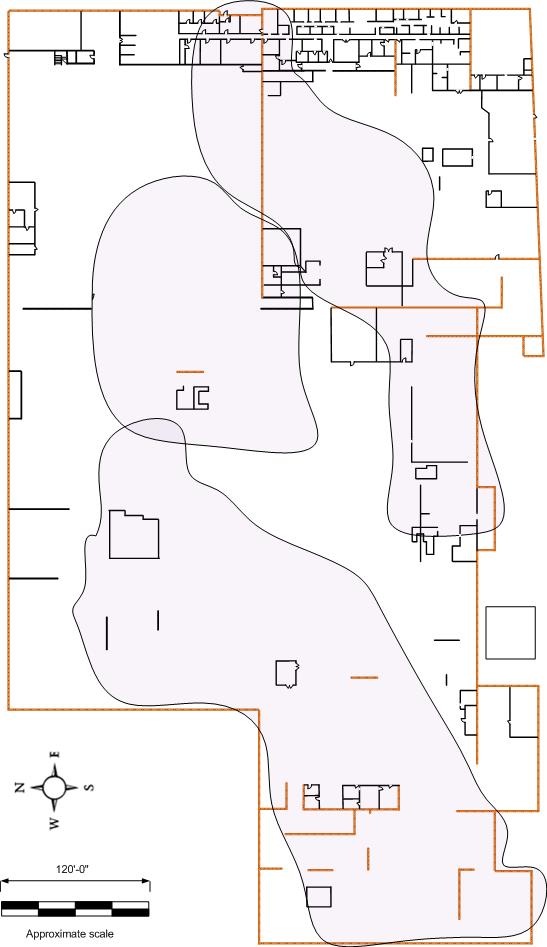

The first factor to be determined is the extent of the plum. This can be plotted on a floor plan using the measurements that have been obtained and the levels that are above guidelines. Typically there have been limited measurements and the exact area of the plum is not fully defined. |

|

|

|

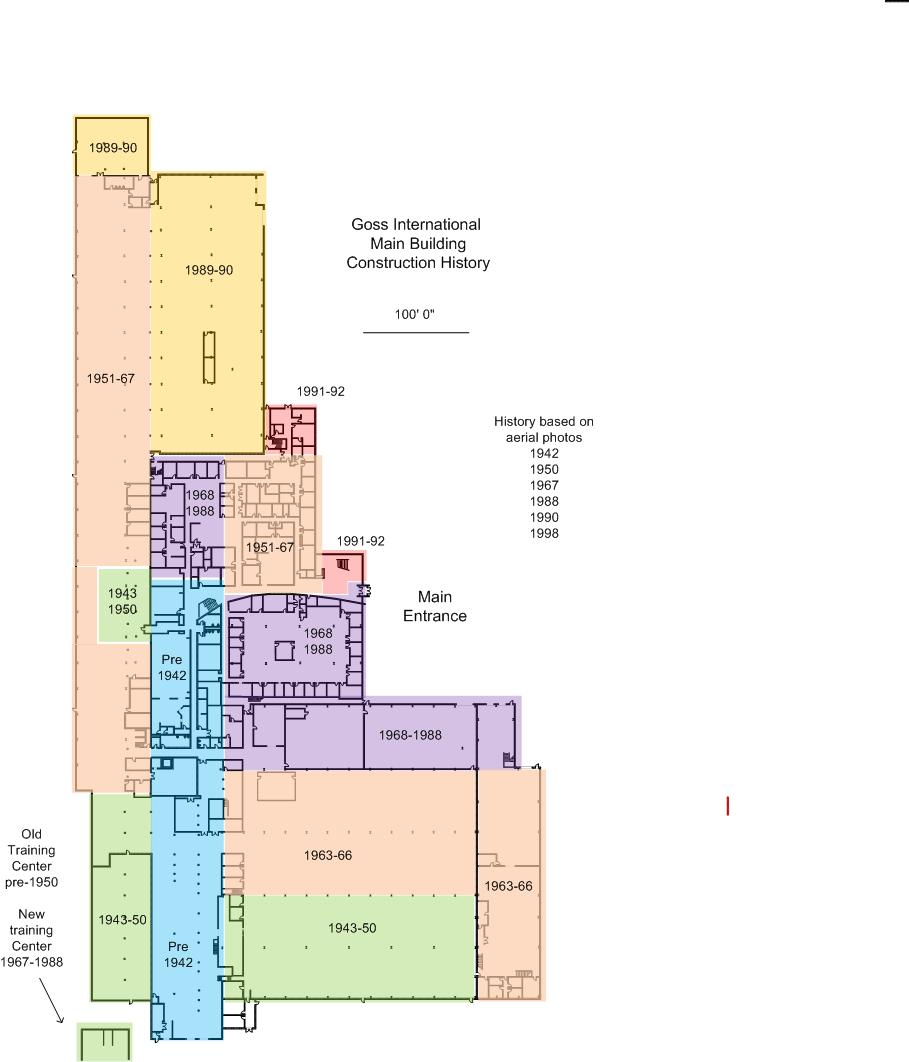

The next step is determining how many additions were installed over the buildings history and what year were those additions built. |

|

|

|

This is a sample of the Sub-Slab Diagnostic Equipment that is brought to the building site to begin the process of measuring the sub-slab pressure field extension characteristics |

|

|

|

A core hole is drilled through the slab in a location that would be appropriate to install a soil venting pipe that can be routed to an extraction fan on the roof or outside the building. We have designed specific equipment to provide sub-slab data. Special equipment is used that will detect if the drill touches sub-slab metal. In many cases the drilled areas have to be scanned to determine they are free of utility piping. |

|

|

|

Multiple smaller 3/8" test holes are drilled through the slab at varying distances in each cardinal direction from the main suction hole. The pressure difference between the sub-slab and the room is measured with the vacuum fan off and at varying airflows out of the suction hole. |

|

|

|

Sometimes it is important to determine the building leakage and the amount of outdoor air needed to pressurize the building. In this case we needed a triple blower door to induce enough pressure change. Published paper has additional information about Blower Door Testing Multiple smaller 3/8" test holes are drilled through the slab at varying distances in each cardinal direction from the main suction hole. The pressure difference between the sub-slab and the room is measured with the vacuum fan off and at varying airflows out of the suction hole. |

|

|

|

If the building has crawl spaces it may be necessary to measure the air quality first before entering. |

|

|

|

We have a large blower available to ensure safe working conditions in areas with limited ventilation. |

|

|

|

This PVC pipe with the fan mounted on the roof is depressurizing 60,000 square feet of this 1/2 million square foot warehouse. |

|

|

|

Commercial buildings typcally have steel re-enforced concrete that requires diamond core drills. |

|

|

|

A strip mall was built over an abandon land fill. This explosion proof fan was used with the sub-slab depressurization system to eliminate Methane inside the building The technician is measuring the Methane in the exhaust Published paper about VOC mitigation |

|

|

|

The depressurization fan should be installed outside the conditioned space of the building and twenty feet away from any building inlet vents. |

|

|

|

This residential building was over a mine shaft and had excessive airflow from the soil requiring two fans to depressurize the sub-slab. |

|

|

|

Sometimes the only place the piping can be run is on the outside of the building. Example of WPB VIM - VOC and Mitigation Design

Residential PFE Testing Guidance |

|

|

|

This sub-slab depressurization system was installed on military base housing in Okinawa Japan. |

|

|

|

In this case the piping was routed up the outside but the fan was located on the roof. Published paper about School Mitigation |

|

|

|

A magnehelic gauge to indicate system operation can be located near the piping or in a remote location. Labels indicate who to call for service |

|

|

|

This was a large factory in Michigan with VOC's that we designed a sub-slab depressurization system for. Example of WPB VIM - VOC and Mitigation Design

A separate page describes how we perform residential PFE Testing Procedures |

|

|

|

If you have any questions please feel free to call Bill at 610 346-8004 |

|

Importance of Diagnostics

|

|

Commercial buildings are rarely built on clean gravel. Determining the ease of airflow under the slab and the distance and strength pressure fields can be obtained with increasing negative pressure applied to the sub-slab is crucial to designing and installing an efficient and effective system. The long term energy costs of operating an oversized system can far exceed the initial installation costs. WPB always recommends that accurate and thorough sub-slab pressure field extension (PFE) tests (also called sub-slab communication tests) be performed first before any active soil depressurization (ASD) system is designed and installed. How we accomplish these tests and and use the obtained information is presented below. A separate page describes how we perform residential PFE Testing Procedures |

|

|

|

The first factor to be determined is the extent of the plum. This can be plotted on a floor plan using the measurements that have been obtained and the levels that are above guidelines. Typically there have been limited measurements and the exact area of the plum is not fully defined. |

|

|

|

The next step is determining how many additions were installed over the buildings history and what year were those additions built. |

|

|

This is a sample of the Sub-Slab Diagnostic Equipment that is brought to the building site to begin the process of measuring the sub-slab pressure field extension characteristics |

|

|

A core hole is drilled through the slab in a location that would be appropriate to install a soil venting pipe that can be routed to an extraction fan on the roof or outside the building. We have designed specific equipment to provide sub-slab data. Special equipment is used that will detect if the drill touches sub-slab metal. In many cases the drilled areas have to be scanned to determine they are free of utility piping. |

|

|

|

Multiple smaller 3/8" test holes are drilled through the slab at varying distances in each cardinal direction from the main suction hole. The pressure difference between the sub-slab and the room is measured with the vacuum fan off and at varying airflows out of the suction hole. |

|

|

|

Sometimes it is important to determine the building leakage and the amount of outdoor air needed to pressurize the building. In this case we needed a triple blower door to induce enough pressure change. Published paper has additional information about Blower Door Testing Multiple smaller 3/8" test holes are drilled through the slab at varying distances in each cardinal direction from the main suction hole. The pressure difference between the sub-slab and the room is measured with the vacuum fan off and at varying airflows out of the suction hole. |

|

|

|

If the building has crawl spaces it may be necessary to measure the air quality first before entering. |

|

|

|

We have a large blower available to ensure safe working conditions in areas with limited ventilation. |

|

|

|

This PVC pipe with the fan mounted on the roof is depressurizing 60,000 square feet of this 1/2 million square foot warehouse. |

|

|

|

Commercial buildings typcally have steel re-enforced concrete that requires diamond core drills. |

|

A strip mall was built over an abandon land fill. This explosion proof fan was used with the sub-slab depressurization system to eliminate Methane inside the building The technician is measuring the Methane in the exhaust Published paper about VOC mitigation |

|

|

|

The depressurization fan should be installed outside the conditioned space of the building and twenty feet away from any building inlet vents. |

|

|

|

This residential building was over a mine shaft and had excessive airflow from the soil requiring two fans to depressurize the sub-slab. |

|

Sometimes the only place the piping can be run is on the outside of the building. Example of WPB VIM - VOC and Mitigation Design

Residential PFE Testing Guidance |

|

This sub-slab depressurization system was installed on military base housing in Okinawa Japan. |

|

In this case the piping was routed up the outside but the fan was located on the roof. Published paper about School Mitigation |

|

A magnehelic gauge to indicate system operation can be located near the piping or in a remote location. Labels indicate who to call for service |

|

This was a large factory in Michigan with VOC's that we designed a sub-slab depressurization system for. Example of WPB VIM - VOC and Mitigation Design A separate page describes how we perform residential PFE Testing Procedures |

|

If you have any questions please feel free to call Bill at 610 346-8004 |

|